Product

Contacts

Add:No. 588, Jinping Road, Shipai, Bacheng Town, Kunshan City, Jiangsu Province

Tel:021-60406718

Fax:021-60406722

E-MAIL:sales@shcarthing.com

Peen Forming Machine

Peen Forming Machine

Date:2018/3/15 15:23:35 Hits:6534

Introduction

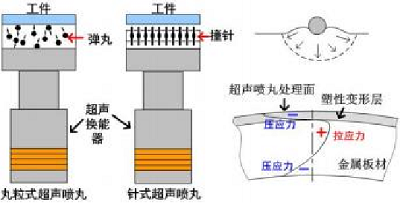

Peen forming process is a kind of forming method which uses the high speed metal pellet to spray metal plate surface, which causes the surface material to produce plastic deformation, resulting in the residual stress field and the curvature of the shape.

The high speed metal pellets spray onto the plate surface, which causes the surface material to produce plastic deformation and pits, and the surface area of metal plate is increased, so that compressive stress is generated in the tangential direction of the plate surface. A large number of metal pellets produce numerous pits on the surface of plate, and the indentations overlap each other, the surface material of a certain depth is extended, resulting in the surface area to be increased, and the metal plate is bent and deformed.

Peen forming process has strong adaptability which also can keep the part material properties and surface integrity. Meanwhile, the strengthening effect will improve the fatigue performance and the overall performance.

Peen Forming Machine

Applicable shot: Steel ball, stainless steel ball, ceramic ball etc.

Features: Meet AMS-2430、AMS-2432、AMS-S-13165、MIL-S-13165C、SAE J442、HB/Z 26 standards etc.

Equipped with industrial robots、mechanical arm as gun movement device and workpiece movement device to realize multi-axis control.

Digital closed-loop shot peening pressure control system, accuracy within ±1%, programmable stop limits;

Digital closed-loop media flow rate control system, accuracy within ±5%, programmable stop limits;

Double layer continuous peening system, automatically add shots;

Mechanical media recovery system

Shots are recovered after the dust separation, size separation and shape separation to keep the consistency with the initial shots;

Reserve jet cleaning cartridge dust collector;

Carthing V1.0 shot peening software with Chinese and English interface based on WINDOWS 7 OS;

Noise≤ 75dB(A)

Dust emission <5mg/m³

Peen forming process is a kind of forming method which uses the high speed metal pellet to spray metal plate surface, which causes the surface material to produce plastic deformation, resulting in the residual stress field and the curvature of the shape.

The high speed metal pellets spray onto the plate surface, which causes the surface material to produce plastic deformation and pits, and the surface area of metal plate is increased, so that compressive stress is generated in the tangential direction of the plate surface. A large number of metal pellets produce numerous pits on the surface of plate, and the indentations overlap each other, the surface material of a certain depth is extended, resulting in the surface area to be increased, and the metal plate is bent and deformed.

Peen forming process has strong adaptability which also can keep the part material properties and surface integrity. Meanwhile, the strengthening effect will improve the fatigue performance and the overall performance.

Peen Forming Machine

Applicable shot: Steel ball, stainless steel ball, ceramic ball etc.

Features: Meet AMS-2430、AMS-2432、AMS-S-13165、MIL-S-13165C、SAE J442、HB/Z 26 standards etc.

Equipped with industrial robots、mechanical arm as gun movement device and workpiece movement device to realize multi-axis control.

Digital closed-loop shot peening pressure control system, accuracy within ±1%, programmable stop limits;

Digital closed-loop media flow rate control system, accuracy within ±5%, programmable stop limits;

Double layer continuous peening system, automatically add shots;

Mechanical media recovery system

Shots are recovered after the dust separation, size separation and shape separation to keep the consistency with the initial shots;

Reserve jet cleaning cartridge dust collector;

Carthing V1.0 shot peening software with Chinese and English interface based on WINDOWS 7 OS;

Noise≤ 75dB(A)

Dust emission <5mg/m³

Previous:

Flap Peening

Next:

Ultrasonic shot peening

CHINA

CHINA ENGLISH

ENGLISH