Product

Contacts

Add:No. 588, Jinping Road, Shipai, Bacheng Town, Kunshan City, Jiangsu Province

Tel:021-60406718

Fax:021-60406722

E-MAIL:sales@shcarthing.com

Projectile & Abrasive

Ceramic pill

Date:2018/7/12 10:18:19 Hits:4182

Product Description

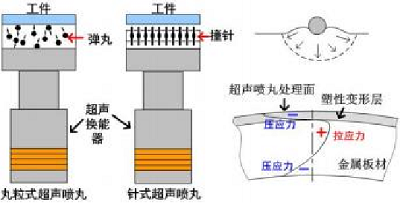

ZIRBLAST and ZIRSHOT ceramic beads are manufactured from metal oxides by "capacitance" processing. The internal structure is characterized in that the zirconia crystal phase is closely arranged in a silica glass phase in a stacked shape. The high hardness produced by this combination gives the ceramic beads extremely high impact strength.

ZIRBLAST ceramic beads are used for ordinary surface treatments such as: cleaning, deburring, polishing

ZIRSHOT ceramic beads are specially used for pre-stressing (surface strengthening) and forming processes. The process requires that the pellets have similar sphericity and similar size.

Journey Path

Compressed air, dry process and wet process;

Turbine

Projectile characteristics:

High impact strength;

Dust contamination effect is extremely low;

Uniform surface roughness;

Less crusts;

No metal contamination (FE2O3: no more than 0.1%);

Full plasticized metal depth

Projectile specifications:

ZIRBLAST Ceramic Beads

Label | Conventional diameter | |

| Mesh | mm |

B20 B30 B40 B60 B120 B125 |

20/30 30/40 40/60 60/120 120/200 一120 |

0.600-0.850 0.425-0.600 0.250-0.425 0.125-0.250 0.070-0.125 0-0.125 |

Label | Conventional diameter | |

| Mesh | mm |

Z850 Z600 Z425 Z300 Z210 |

16/20 20/30 30/40 40/50 50/70 |

0.850-1.180 0.600-0.850 0.425-0.600 0.300-0.425 0.210-0.300 |

Quality Test

Both ZIRBLAST and ZIRSHOT ceramic beads have been rigorously tested by the company's experimental center

ZIRBLAST ceramic beads meet the French NFL06.824 standard

ZIRSHOT ceramic beads meet the following criteria:

-NF L06.831

-SAE J1830

-AMS2431 and 2431/7

-MIL-S-13165C

Typical Crystal Phase Analysis

Zirconium oxide 68% Glass phase 32%

Physical Performance

Theoretical density | 3.85 | True weight | 3.76 |

hardness(HRC) | 50-65 | False weight | 2.3kg/l |

Previous:

Wire cutting pill

Next:

glass bead

CHINA

CHINA ENGLISH

ENGLISH